Solutions

Digital Twins

Learn how we help businesses become smarter, save cost and drive sustainable operations.

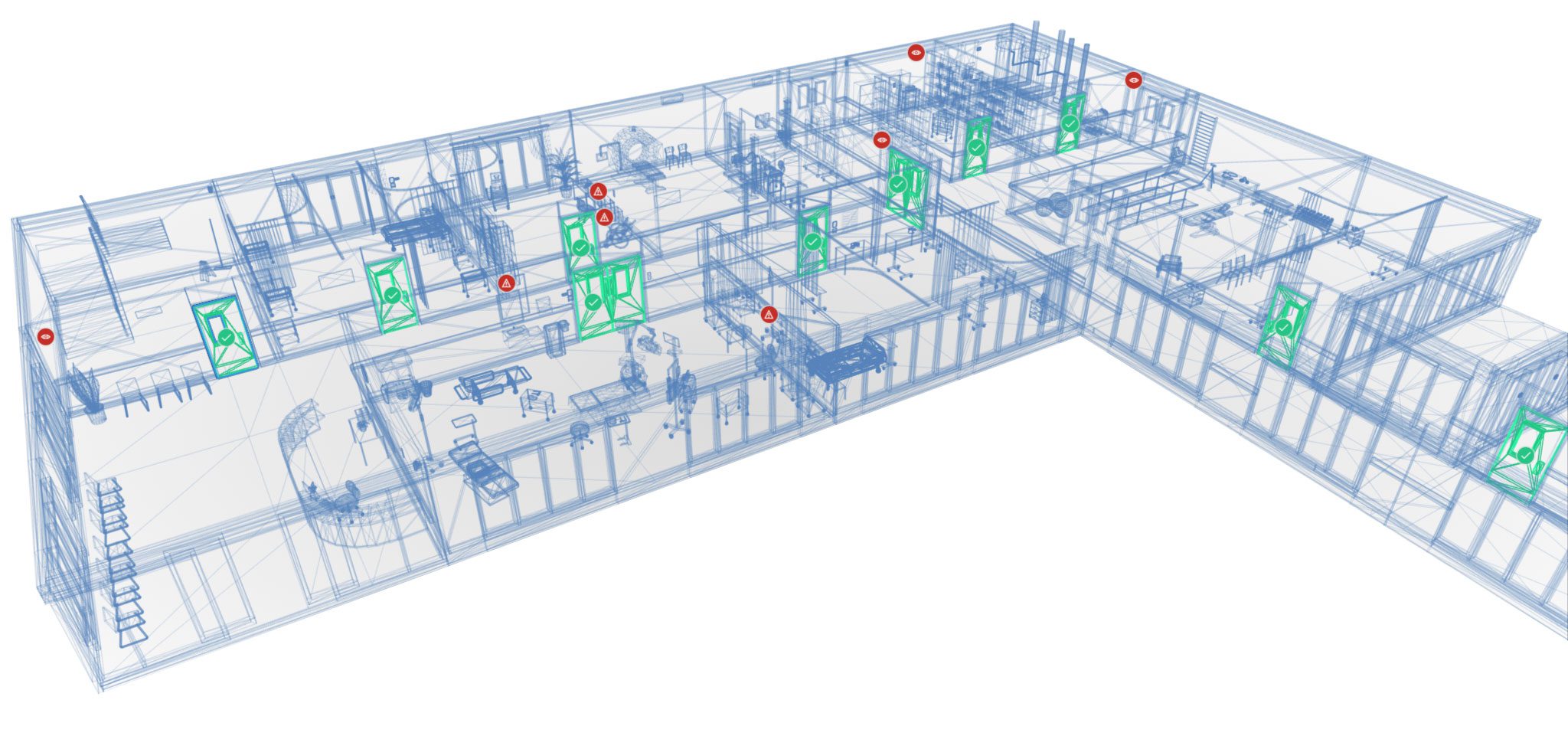

Innovate Smarter with Digital Twins

Our digital twins are a virtual representation of a physical object or system that can be used to simulate and analyse its real-world behaviour. We use data from sensors, IoT devices and other sources to create an accurate, real-time replica of the physical object or system.

Digital Twins

SIMULATIONS

We include simulating the asset’s response to different loads, environmental conditions and control inputs.

Smart Operations

Gain valuable insights into the performance and behaviour of your equipment, assets and processes, allowing you to identify and resolve issues quickly and improve overall efficiency.

Data Collection

Collect data from the physical asset, such as sensor readings, images, and other measurements.

Modelling

Create a digital representation of the physical asset using computer-aided design or building information modelling.

Event-Driven Response

Use digital twins to automatically manage and respond to critical events happening in real-time.

Simulation

Use the model to simulate the behaviour of the physical asset under different conditions.

Simulate. Optimise. Transform.

Digital Twins can be used in various industries such as manufacturing, energy, construction, transportation and many more. They can be used for monitoring, simulation and optimisation of equipment and systems, enabling organisations to improve their performance and reduce downtime.

For example, in the manufacturing industry, a digital twin can be used to simulate the entire production process, from the design stage to the final product. This allows manufacturers to optimise the production process, identify potential issues and improve the overall efficiency of the production line.

In the construction industry, a digital twin can be used to simulate and optimise the construction process, reduce waste and improve safety. It can also be used for monitoring and managing the performance of completed buildings, facilities and infrastructure.

Sustainable Future

Smarter

Work with us to deliver a smart future for the next generation.

The future of monitoring and optimisation

Continual Update

Continuously update the digital twin with new data as it becomes available to keep it as accurate as possible.

Integration

Integrate the digital twin with other systems, such as control systems, monitoring systems, and analytics platforms. This allows the digital twin to provide real-time insights into the asset's performance and to be used for control and optimisation.

Validation

Compare the results of the simulation to the real-world behavior of the asset. This can be done by comparing simulated results to data collected from the physical asset.

The full package

Whatever you need, whenever you need it. We boast a network of software specialists that will help support your teams to launch your business solutions.

Expertise where you need it

We work with you to meet the challenge. Our team will augment existing teams and operations to help your people deliver the exceptional.

Connecting With You is Our Starting Point

We look to understand you before looking to be understood. It's your journey and we help realise the opportunity to get the most out of your applications.

Trust Us - You're in Good Hands

We won't let you down. We are on-hand 24/7 to get you moving. No matter the challenge or project, talk to us to find out how we can partner with your business.

[ TESTIMONIAL ]

Game-Changing AI Transformation. Exceptional Results

Highly Recommended

I can’t recommend these guys enough. I’ve collaborated on many projects with Gary and his team. Their delivery, cadence and knowledge are the best I’ve come across.

Mark Boulter

Liv Golf

Unparalleled

Gary’s attention to detail is unparalleled. I’ve worked on multiple projects with the team, every time the outcome is outstanding and exactly to spec.

Alex Booth-Lowe

William Reed

Meaningful Value

It’s clear to see Blundens is modelled on a human-centred approach that delivers meaningful value. The project they delivered for me will absolutely do that.

Isaac Downes

Cadre-Connect